After a few months, it’s time to talk about what has happened with the irrigation system in the mean time.

There are a few different small improvements that all add up to a very different system in the end.

This is part 5 of this series; here is part 1, part 2, part 3, part 4.

Productionizing

I started packaging each sensor together with its silicon tube so that it would be easy to move the entire ordeal to new plants when necessary.

All tubes can drain from a common cistern that gets refilled periodically. There are a few precautions around it to not cause a flood in case one of the pumps malfunctions; the most important being that the cistern only contains so much water, so when it runs out there’s only so much water that can end up on the floor.

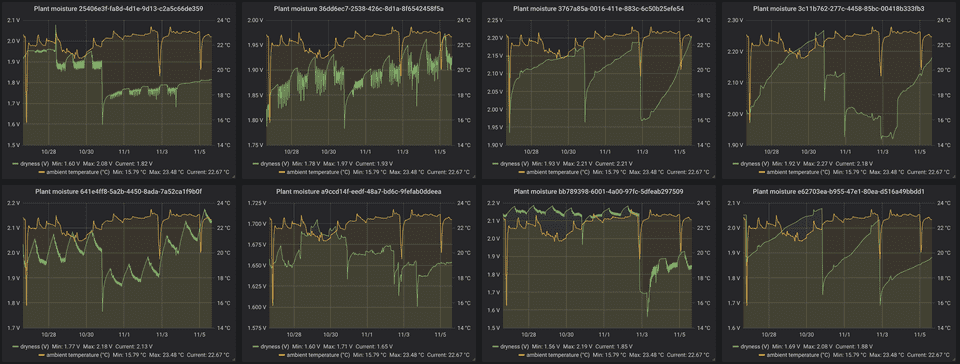

This means that it gets easy to reason about the pumps and sensors at scale, and I can use modern monitoring tools such as InfluxDB and Grafana to get nice monitoring dashboards for everything. For fun, I added a BMP280 chip to measure temperature and air pressure to correlate with the moisture data.

The zig-zag pattern comes from the pumps running, of course. The final result looks quite neat:

…and the full set-up now supports all 8 plants, even though there is no space in my windowsill.

Chemistry sucks

Putting electricity through soil is probably one of the easiest ways of measuring moisture. The problem is that there’s an anode and a cathode, and since I’m using DC it means that they both corrode over time. This is neither good for the plants, since the soil fills up with tin and copper and nickel, nor for me since I have to keep replacing the anodes and cathodes every few weeks.

After a while, I realized it was time to invest in a more scalable solution. I got a hold of some capacitive moisture sensors, which makes it possible to measure the moisture content without the circuit coming into contact with the soil (similar to how your phone touch screen does not elecrify your finger).

I sealed off the sensors with clear lacquer to make them extra water proof:

Using these sensors worked great. The only annoying thing was that each sensor now required 3 cables instead of 2: An anode/cathode only require a +/- lead, while now I need power for the capacitive signal generator (+/-) as well as a separate signal for the sensor reading (which still uses an analog signal for now, since the ADCs were already set up for that).

Swedish winter

Since it’s now getting darker and darker in Sweden, there’s one more dimension to be controlled with this plant set-up: the lights. It makes sense to simply hook up UV lights to this contraption. For now, they are manually controlled, but eventually they should also be controlled by the same controller program as the rest of the set-up: